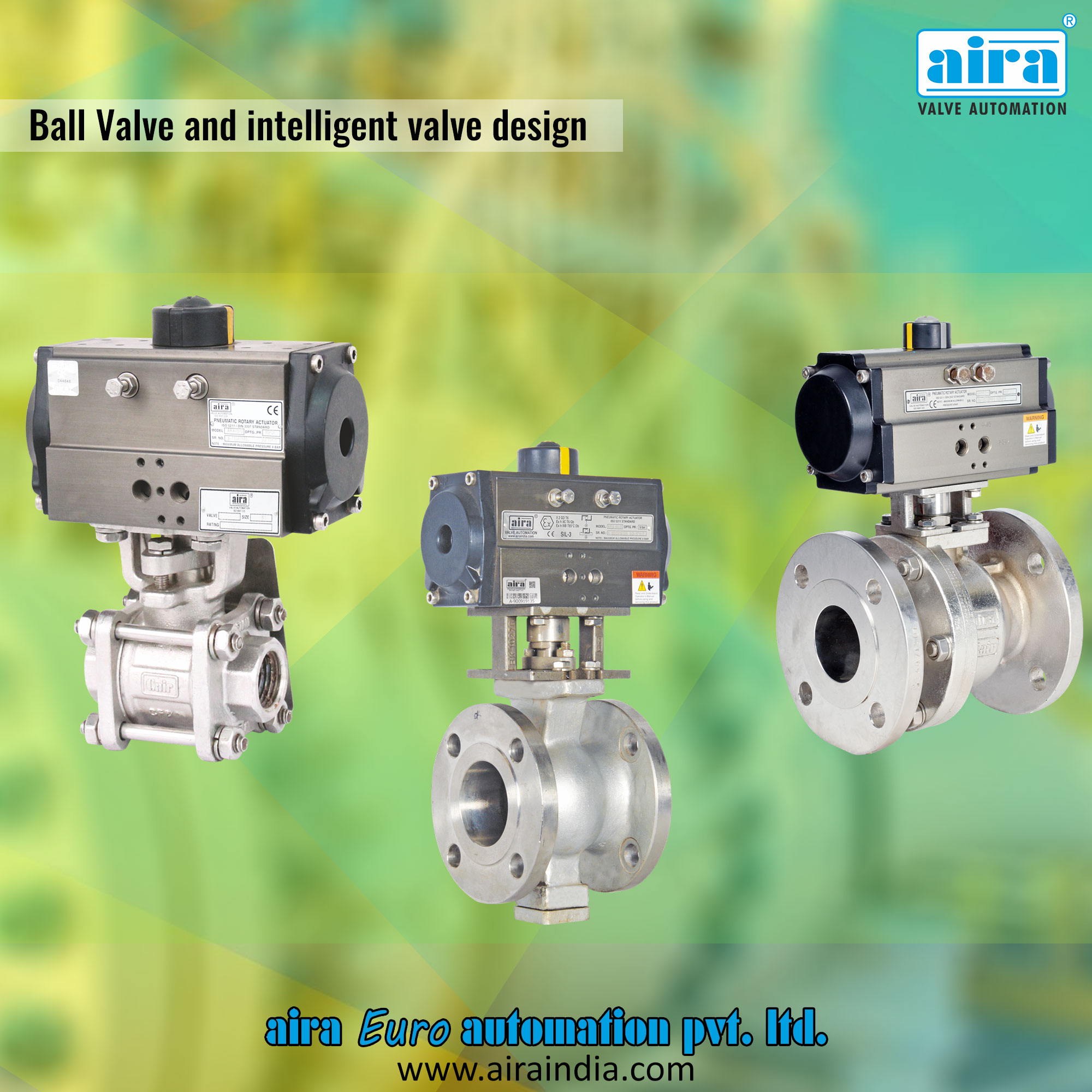

Ball Valve and Intelligent Valve Design

A ball valve is a quarter-turn on/off the device. The flow of liquids or gases is controlled by a pivoting ball at the center of the valve.

Pivoting balls are called rotary balls, and they are designed with holes (bores) in the center. To open or close the valve, the ball is rotated by a stem on top of the ball. Manual levers or automation can be used to turn the stem.

Construction :

A ball valve consists of a body, a spherical plug, and seats. A ball valve can be made in three general patterns:

- venturi port,

- full port and

- reduced port.

– A full-port valve has an inside diameter equal to the pipe’s diameter.

-Venturi and reduced-port styles have a port that is generally one pipe size smaller than the line. The sealing of the stem is achieved with bolted packing glands and O-ring seals.

There are also valves with lubricant-seal systems similar to those for plug valves.

Ball valves are usually made from steel, iron, brass, bronze, or PVC.

People would like to read Butterfly Valve Maintanance Guide

Benefits :

- Ball valves offer several distinct advantages over other types of valves:

- Compact and economical designs

- Quick shut-off times

- High-pressure, high-volume, and high-temperature-resistant

- Less susceptible to corrosion or damage

- Longer lifespan

Perfect for a wide range of industrial applications

Floating Ball Valve & their benefits :

In industrial piping systems, floating ball valves are the most common type of valve. The ball of these valves is designed in such a way that as the seats wear, the pressure from the flowing media will force the ball against the downstream seat to maintain a tight seal.

Floating ball valves are most commonly used in applications that require medium to low-pressure valves and are suitable for both liquids and gases.

Benefits :

- Convenient design

- Cost-effective

- Personalized

- Low resistance to flow

- Reliable sealing mechanisms

- Easy to assemble

Trunnion Ball Valve & their benefits :

In trunnion mounted ball valves, the ball is supported by a second stem opposite the operating stem, similar to floating ball valves. The second stem and bearing are called the trunnion.

Ball Valve

The stem of a trunnion ball valve is rigidly attached to the ball, preventing the ball from moving anywhere other than on its axis. The trunnion ball valve maintains a proper seal on both sides simultaneously since the ball does not move downstream with the pressure. It is especially critical for multiport valves and valves used in very low-pressure applications where the flow of media is not strong enough to push the ball against the downstream seat.

Trunnion valves are useful in both low and high-pressure applications and require less torque to operate than floating ball valves. Despite this, piping system designers should note that trunnion ball designs are generally more expensive than floating ball designs.

Benefits :

- Lower operation cost

- Effective in both low and high-pressure situations.

- Useful for the facilitation of hydrocarbon processing

- Ball valves are fitted with spring-loaded seats

V Notch Ball Valve & their benefits :

- Valve with V-Notch is a quarter-turn valve ball segment.

- The V-Ball creates a wedging effect.

- The shearing action prevents stock from being dragged or sludged between the ball and its seal

- V-Notch Ball Valves are squared and clamped with a driven shaft.

Most commonly, a contoured V-port in the ball is available with an angle of 15°, 30°, 45°, 60°, or 90°, which produces an equal percentage flow characteristic. As compared to more expensive and larger control valves, V-ball valves offer a variety of benefits for flow control applications.

Benefits :

- The pressure drop is low.

- Bubble tight shut off.

- Flow control is precise.

- There is a high shut-off pressure.

Lined ball valve

Lined Ball Valves consist of a body, stem, ball, seat, and lining.

The interior is completely lined with high-quality PTFE or PFA lining material which, due to its thickness, completely protects the valves against chemical corrosion. It is an ideal choice for nasty applications.

Lined Ball Valves consist of a body, stem, ball, seat, and lining.

Multi-port ball valves & their benefits

It is a type of ball valve that has generally more than two ports and can be controlled in either 3, 4, or 5 ways, depending on the application. The process is typically used for selecting several flow paths to ensure the process continues according to the customer’s requirements.

Benefits :

Multi-port ball valves significantly reduce corrosion in tank installations, valve manifolds, and pipe systems.

Valves with multiple ports can be equipped with position indicators, pneumatic or electric actuators, lockouts and targets, and multiple ball structures

Designed to significantly reduce dead legs while maximizing drainage.

Conclusion :

We at Aira Euro automation are a leading manufacturer, supplier, and exporter in the UAE. Our Actuated Ball Valves are used for Oxygen Applications. Our corrosion-resistant ball valves have been designed by a team of expert engineers with years of experience in the field. We gained API certificates for various quality parameters. As every product has to match the standard quality guidelines because our quality department manually tests each product to ensure safety & security before delivery. Not only in the UAE, but we are the global supplier of industrial valves.